+91 75987 34364

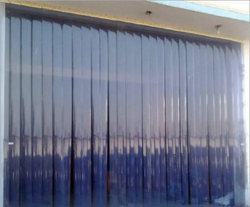

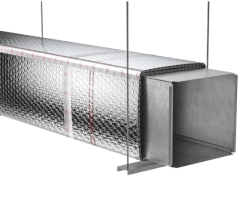

FRP Ducting

FRP humidification ducts are widely utilized in textile industries to address corrosion issues commonly found in GI ducts.

At present we are doing projects on spinning, weaving, OE (open end) mills in textile industrials. Also we had done almost 20+ projects in this. Meanwhile we are doing more projects in this.

Benefits of FRP Ducts Compared to GI Ducts:

- FRP ducts are corrosion-resistant, unlike GI ducts that corrode under humid conditions. This is particularly useful in spinning mills for areas such as Autoconer, Preparatory, and Blow rooms.

- The glossy inner surface of FRP ducts facilitates easier cleaning and maintenance.

- FRP ducts can be produced in various shapes, including circular, rectangular, and square designs:

- Circular ducts are preferred for the following reasons:

- More cost-effective than other shapes

- Optimized design

- Uniform load distribution

- Easier and more cost-efficient manufacturing

- Circular ducts are preferred for the following reasons:

- FRP ducts act as natural insulators, eliminating the need for extra insulation, which helps reduce costs.

- FRP ducts are lightweight, weighing only a quarter of GI ducts, making them easier to transport and handle.

Pollution Control Equipment:

We manufacture components like scrubbers, absorbers, towers, separators, blowers, and stacks to meet global pollution control standards. These are made using materials suitable for various service environments and are lined with thermoset or thermoplastic materials.

FRP Lining:

We offer FRP lining services on materials like MS, RCC, and wood surfaces at both our factory and customer locations. Extensive FRP lining work can also be completed directly at client premises.

Erection Services:

We provide not just the supply of pipes, fittings, and ducts but also their full installation and erection at project sites on a turnkey basis.